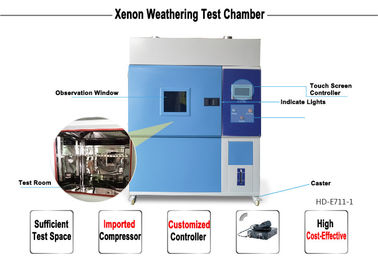

Sunlight, heat and moisture cause millions of dollars in product damage every year. Cracking, crazing, hazing, fading and yellowing can occur indoors or outdoors. With Full Spectrum Xenon Aging Chamber ISO xenon lamps Accelerated Aging Chamber, you can simulate the damage caused by full-spectrum sunlight, temperature and moisture. In just a few days or weeks, xenon lamps Accelerated Aging Chamber can reproduce the damage that occurs over months or years outdoors

Key Features:

Remarkably Simple User Interface

AUTOCAL Calibration

Full Spectrum Xenon Lamps

Long-Life Optical Filters

Programmable Water Spray

SOLAR EYE Irradiance Control

Precision Temperature Control

Versatile Specimen Mounting

Relative Humidity Control

Auxiliary Structure:

Seal: double high-temperature high tensile seal between the door and the cabinet in order to ensure that the test area

Door handle: no reaction door handle, easier to operate

Moves the sample holder: Sample holder rely installation box at the bottom of the linear reciprocating drive system for moving up and down

Casters: bottom of the machine can be fixed with high quality PU wheels

Specifications:

| Model |

HD-711L Xenon Lamp Aging Chamber |

| Inner Box Size (D×W×H) |

950×950×900mm |

| Outside Dimension (D×W×H) |

1300×1500×1900mm |

| Humiture Range |

(RT+10)~70°C; 30~98%RH |

| Humiture uniformity |

± 2°C; ± 3%RH |

| Rainfall time |

1~9999min, adjustable |

| Rainfall cycle |

1~240min, interval is adjustable |

| Xenon lamp light |

xenon long-arc lamp, 6KW±10%, 290-800nm, 1000W/m2±200 |

| Heating/humidifying power |

2.0KW/2.0KW |

| Sample spinning machine speed |

1~5r/ min (adjustable) |

| Sample and xenon lamp distance |

300~375mm |

| Box material |

Stainless Steel SUS304# |

| Insulation materials |

Superfine heat insulation cotton |

| Insulation body |

Superfine glass fabric |

| Circulation system |

Single cycle, centrifugal fan |

| Control system |

Germany KLOCKNER-MOELLER progammable controler |

| Gas processing |

dischager for fector and harmful gas |

| Power |

AC380V, three phase five wire, 10KW |

| Use environment |

5°C~+30°C, ≤85%R.H |

| Standard features |

1. Filtering screen viewing window; 2.Moistureproof lamp |

| Security Protection |

Security device for circuit break, |

| high pressure of the compressure, high temperature alarm |

Simple to Maintain:

We believe that just because a product is technical, it doesn’t have to be hard to understand or difficult to maintain and repair. Instead of complicating our tester designs by loading them with extra or unnecessary features, we put our engineering effort into keeping things simple. Subsystems are modular, easy to troubleshoot and even easier to replace.

Operation:

2.0KW Heating Xenon Arc Accelerated Aging Chamber Weathering Test Equipment are extremely simple to operate. Specimen mounting and evaluations are simplified with specially designed specimen holders. Programming is intuitive. All models are completely automated and can operate continuously, 24 hours per day, 7 days per week.

Simple to Afford:

2.0KW Heating Xenon Arc Accelerated Aging Chamber Weathering Test Equipment were specifically designed to have the lowest total cost of ownership in the industry. Their low purchase price, low lamp price, and low operating costs set a new standard for lightfastness testing. Now even the smallest lab can afford xenon arc weathering and lightstability testing.

Maintenance:

1, any time to maintain a neat appearance;

2. Do not place objects on top of the machine to heat parts of Lima Da and control;

3, xenon lamp aging chamber after long-term use, spare parts, motor blower unit, wheel deceleration devices, if abnormal noise, should be checked, and pay attention to regular cleaning fuel;

4, electrical components such as over-temperature phenomena, must be checked immediately causes;

5, after each use, a xenon lamp aging test chamber should be kept clean to prevent corrosion;

6, the control cabinet clean-up once a month to prevent excessive dust, affecting the normal operation of equipment;

7. After the test is complete, you should turn off the main power, water stains wipe clean indoor work, try to keep the chamber in a dry environment;

8, the electrical components on the control panel, such as the need to exchange failure occurs, Do not indiscriminate demolition ensure xenon lamp aging chamber life.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!