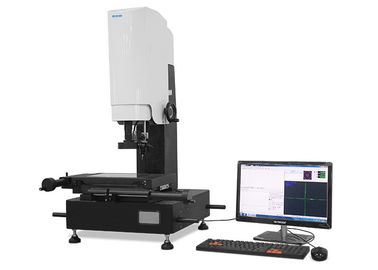

2D Coordinate Image Optical Measuring Equipment Programmable

Programmable 2D Coordinate Optical Precision Image Test Machine is a precise and effective non-contact optical measuring instrument. It is composed of a series of accessories, such as color CCD Camera & adapter, zoom lens capture card, linear scales, high precision worktable, electronic motor, PC and monitor.

The Main Technical Parameters:

| Model |

TT-U801 2D Coordinate Optical Precision Image Test Machine |

| Glass table size |

320×280mm |

| Travel: X,Y |

400×300mm |

| Net Weight |

240 kg |

| Dimension |

750×600×920mm |

| Travel: Z : 150mm |

Work distance: 95mm |

| Video system |

Camera: Color 1/3``CCD camera |

| Optical Magnification:0.7~4.5X |

| Digital magnification:30~230X |

| Object view-field:8.1~1.3mm |

| Contour and surface illumination: Ring LED and brightness can be setup |

| Power |

180V(AC)-260V(AC) 50Hz |

| Software |

Quick Measuring 2.0 |

Features of Programmable 2D Coordinate Optical Precision Image Test Machine:

1 > Creative modern-shape-design;

2 > Fashionable auto-painting-craftwork ;

3 > Steady granite base;

4 > Stable imported V-shape guide;

5 > Precise metal and glass worktable;

6 > High-speed 3-axis CNC driven motor;

7 > Adjustable USB 40-division ring LED illumination;

8 > Advanced Pomeas 0.7~4.5X Zoom lens;

9 > Wonderful SONY 1/2`` Color CCD camera;

10> Powerful 2.5D measuring software QuickMeasuring 4.1 version.

the hardware:

1, with marble base, column, precision machinery countertops, good stability, structural rigidity

2, three-stage structure, enhance the mechanical stability, ensure X, Y horizontal movement precision;

3, table X, Y to the vertical high assurance coordinate measurement accuracy, even if the work does not straighten can also achieve high measurement accuracy;

4, single-axis precision linear compensation up to 3 + L / 200, non-linear compensation up to 3 + L / 250;

5, LED light source and the surface contours of light, meet the lighting requirements of different surfaces

6, integrated machine stand, make the operation more convenient, ergonomic;

7, to provide 12 months long warranty and lifetime maintenance, once selected no worries.

the software:

1, the software has a similar EXCEL reporting. Measurement data can be seamlessly connected with the EXCEL data

2. The report data can be directly SPC data analysis

3, automatic output tolerances and are able to colors, sounds, logos alarm, most especially timely for product tracking size.

4, in the image measurement industry was first introduced in the sub-pixel measurement functions, measurement are no professional requirements. Relative to peer products, at least 3/5 of angels to save measurement time, greatly enhance the efficiency measure.

5, do primitive reproduction, translation, rotation, mirroring, the line segment extending, shearing, two wire arc tangent. Tangent point circle.

6, do the vertical, horizontal, diameter, radius, angle dimension;

Measurable distance between two points, the point-to-line distance from the line to the circle, two round distance, center distance line;

7, do shape difference measurements, such as: parallelism, roundness, straightness and so on;

8, you can measure a variety of complex graphics including curves.

9, a powerful shot map capabilities that enable virtual measurement.

maintenance:

1, the instrument should be placed in a clean, dry room (temperature 20 ℃ ± 5 ℃, humidity below 60%), to avoid fouling the surface of optical parts, metal parts to rust, dust and debris falling into the movable rail, affecting the performance of the instrument.

2, the instrument after use, should be ready to wipe clean working surface, the best and then cover dust jacket.

3, transmission equipment and rail movement, should be regularly lubricating oil, so that smooth movement mechanism to maintain good condition.

4, table glass and painted surfaces dirty, you can wipe clean with a mild detergent and water. Never use organic solvents to clean the surface of the paint, otherwise, would tarnish the paint surface.

5, the instrument LED light source long life, but when the bulb burns out, please inform the Central Instrument manufacturers, by professionals for your replacement.

6, precision instrument parts, such as imaging systems, workstations, optical device and Z-axis drive mechanism, etc. are required to fine tune all the adjusting screw and tighten the screws are fixed, customers do not disassemble, any questions please notify the manufacturer solve.

7, the software has been on the bench and the optical scale errors in the fine compensation, do not make changes. Otherwise, it will produce erroneous measurements.

8, the instrument all electrical connectors, generally do not unplug, as has been pulled out, it must be correctly inserted back into the marked and tighten the screw. Incorrect patch, ranging from the instrument function, weight may damage the system.

Programmable 2D Coordinate Optical Precision Image Test Machine view:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!